In a significant shift, Apple has introduced a new stainless steel casing for the batteries used in its iPhone 16 Pro, replacing the aluminum-plastic laminate soft-pack batteries from previous models. This change brings improvements in both energy density and battery capacity across the iPhone 16 lineup.

The battery capacities for the iPhone 16 models are as follows:

- iPhone 16: 3561mAh

- iPhone 16 Plus: 4674mAh

- iPhone 16 Pro: 3582mAh

- iPhone 16 Pro Max: 4685mAh

The incremental improvements in energy density of lithium-ion batteries are largely attributed to advancements in positive and negative electrode materials. Each successive iPhone generation typically features a modest increase in battery capacity. However, it’s uncertain if the shift to a stainless steel battery casing in the iPhone 16 Pro will yield substantial gains in energy density.

This marks the first time Apple has deviated from the traditional aluminum-plastic film pouch battery design. What prompted this change, and what benefits can we expect? Let’s delve into the details.

What is a Metal-Cased Lithium-Ion Battery?

A lithium-ion battery is composed of a positive electrode, a negative electrode, a separator, an electrolyte, and other materials. The outermost layer, or “shell,” used for sealing is primarily made of two materials: metal casing and aluminum-plastic film pouch. These two types of batteries are commonly seen in everyday electronics.

Aluminum-plastic film pouch batteries, also known as “soft pack” batteries, are mainly used in lightweight and portable consumer electronics such as mobile phones, tablets, and laptops. Their characteristics include being relatively lighter and thinner, making them suitable for narrow spaces. In the confined battery compartments of 3C digital devices, soft pack batteries have become the most widely chosen option.

Cylindrical lithium-ion batteries like 18650 and 21700 have a casing that is a stamped “metal tube”. Some large format prismatic lithium-ion batteries used in new energy vehicles also have metal casings. These metal casings are characterized by their hardness and strong protection capabilities. Additionally, button-cell lithium-ion batteries commonly used in watches and other miniature devices also have metal casings.

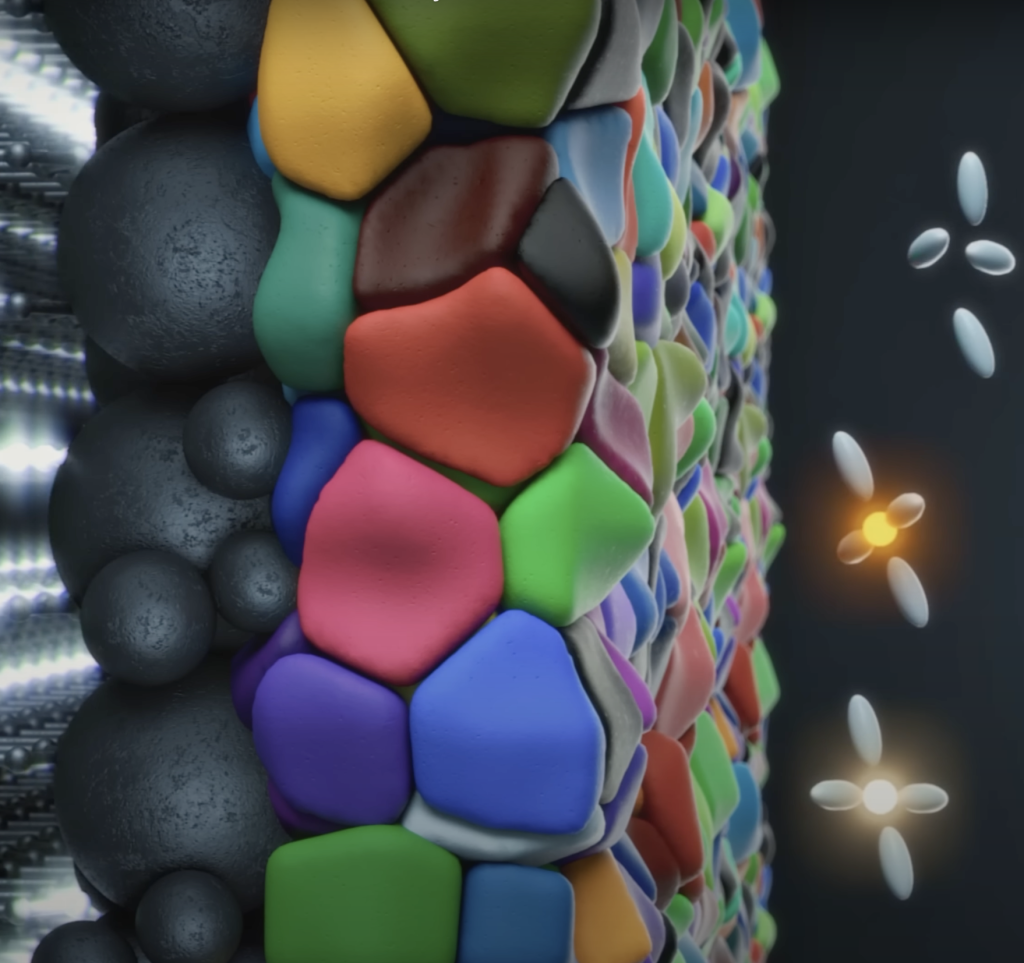

The iPhone 16 Pro uses a stainless steel battery casing that is neither a thick metal casing like the 18650 nor an aluminum-plastic pouch. Instead, it uses a very thin stainless steel sheet welded into a square casing. Its shape is similar to a soft pack battery, making it suitable for lightweight digital devices, but the metal casing provides a more robust surface.

Apple’s History with Metal-Cased Batteries

Apple first began to use metal shell lithium batteries on the Apple Watch S5 smart Watch (left picture above), and a number of subsequent Apple Watches have adopted metal shell lithium batteries.

In terms of appearance, the metal shell battery and the common aluminum-plastic soft-pack battery are square and thin shape, but the surface look is different, and the surface of the metal shell battery shows a matte metal luster. There is also an arc at the negative terminal in the upper right corner of the metal shell battery, which is the explosion-proof pressure relief indentation of the battery.

Advantages of Metal-Cased Batteries

Compared to aluminum-plastic pouch cells, metal-cased batteries are significantly more durable, with a harder surface that is less prone to scratches or damage. When impacted, they deform less, and they can also withstand higher internal pressure. This reduces the likelihood of swelling when gas is produced inside the battery, a common issue with soft-pack batteries.

Additionally, metal-cased batteries allow for better space utilization in the battery compartment. Due to the superior protection offered by the harder casing, there is no need to reserve extra “safety distance.” In terms of wiring, the entire surface of the metal-cased battery acts as the negative terminal, which allows for more efficient design in conjunction with the PCBA.

It is well-known that every generation of iPhone features incredibly powerful processors, with peak performance far exceeding Android counterparts. However, due to the lack of efficient heat dissipation designs like Vapor Chambers, iPhones tend to experience significant performance drops when they heat up. The adoption of metal-cased batteries could improve overall thermal distribution, helping to alleviate the long-standing issue of poor heat management in previous iPhone models.

Possible Reasons Behind the Switch

On June 7, 2022, the EU reached a provisional agreement to make USB-C the standard charging port for small electronic devices by the end of 2024. Later, on October 4, 2022, the European Parliament passed the new law with 602 votes in favor, 13 against, and 8 abstentions. This marked a significant milestone in the years-long process of transitioning consumer electronics to a universal charging interface.

The EU’s consensus mandates that consumer electronics must adopt the USB-C standard interface; devices without it will not be permitted for sale in the European market. Previously, iPhones had consistently used the Lightning port, but due to this EU regulation requiring a common interface for small devices, Apple switched to USB-C with the iPhone 15, finally offering the benefit to consumers.

The shift to a metal-cased battery in the iPhone 16 Pro is also likely influenced by EU policies.

In 2023, the EU overwhelmingly passed another resolution (587 votes in favor, 9 against, and 20 abstentions), requiring portable devices like smartphones, tablets, and cameras to be designed with easily removable and replaceable batteries. This regulation is expected to come into effect as early as 2027.

It’s likely that Apple has already been preparing for this shift to replaceable batteries. However, continuing to use aluminum-plastic soft-pack batteries would increase the risk of users damaging them during the replacement process, potentially leading to fire or explosion—an outcome Apple clearly wants to avoid. The metal casing provides better protection, making the battery safer to handle and less prone to damage or deformation during installation.

Conclusion

The introduction of stainless steel-cased batteries in the iPhone 16 Pro represents a significant upgrade over the aluminum-plastic soft-pack batteries used in previous models. The new design offers enhanced protection for the battery core, better heat dissipation, and could be a step towards future compliance with regulations requiring user-replaceable batteries.